PVC foam tapes, as well as EVA foam tape, are adhesive items that have very broad ranges in many various industries requiring sealing, cushioning, and insulation. Their characteristics are identical since both are foam-based tape products, but each has a considerable difference in raw material properties and useful applications. One must learn the differences to make optimal use of a specific project.

Manufacturing PVC foam tapes means pouring liquid polyvinyl chloride on a casting sheet, heating this to the formation of closed-cell foam, and immediately coating the surface of that foam with adhesive, which negates the need for a release liner. Very easy installation, resource-saving, and cost-saving would make PVC foam tape an ideal candidate for high-volume manufacture. It is offered in low, medium, and high densities for diverse needs.

Low-density PVC foam tapes could be used as a replacement for polyurethane gaskets in weather stripping applications. Medium-density PVC foam tapes are used for superior impact resistance, while high-density versions are used for best cushioning and structural integrity. Because they easily mold to irregular surfaces such as gaps found in log homes or HVAC systems, high-density foam tapes are also preferred.

EVA foam tape is variously produced from ethylene vinyl acetate, which is soft and flexible since it is rubbery in helping shock absorption and vibration damping in sensitive electronics mounting, noise reduction in automotive interiors, and protection of fragile items, transforming them in the form of EVA foam.

EVA foam tape has excellent UV light and chemical resistance; however, it will not match PVC's performance in extreme temperatures or corrosive atmospheres. The elastic nature suits dynamic applications involving the sealing of moving parts or insulating wearable devices. Durability is the calling card of PVC foam tape. Resistant to the attack of solvents, fuels, chemicals, and UV rays, it would prove effective in extreme environments. Closed-cell construction inhibits water absorption, which is a definite advantage for outdoor or industrial applications.

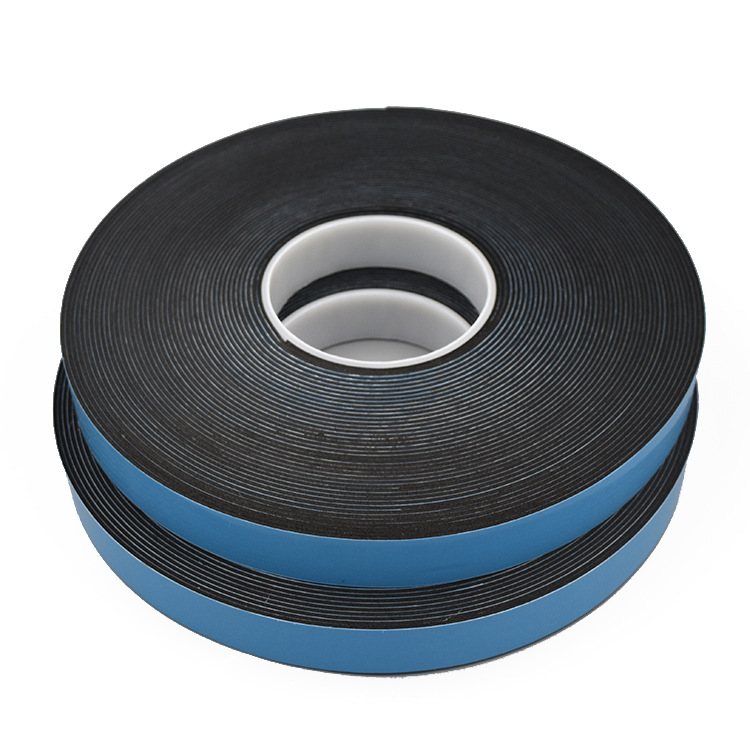

PVC Foam Tapes

Customizable through processes such as roll slitting or die cutting, it can present the solution to unique challenges of such projects as industrial roof seals or automotive vibration dampeners. EVA foam tape emphasizes flexibility and cushioning. We offer single and double-coated adhesive products for specific and unique light bonding requirements.

Applications include electronic assembly, noise attenuation within motor vehicles, and protection packaging. EVA is a lightweight material with elastic properties, making it ideal for applications with movement or impact resistance requirements. The decision here depends mainly on what the particular project requires.

PVC foam tape is the best choice in harsher environments that require durability and resistance to chemicals, such as sealing HVAC ducts or insulating machinery. The tack-free orientation allows for fast and efficient high-volume production. In comparison, EVA foam tape is more preferably used for cushioning electronics, dampening vibrations, or protecting sensitive finishes. PVC foam tape seals joints and insulates pipes in construction, while EVA tape cushions equipment or noise in modular buildings.

In automotive applications, PVC is used to weatherproof the panels while EVA dampens the vibration of the door. The two tapes provide reliable solutions but address differing problems. PVC foam tape is cheap and tough for any industrial job. EVA foam tape is flexible and absorbs shock for precise applications.

Comments on “PVC vs. EVA Foam Tapes: How to Select the Right Tape for Sealing, Cushioning, and Insulation”